Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

| Selling Units | : | Piece/Pieces |

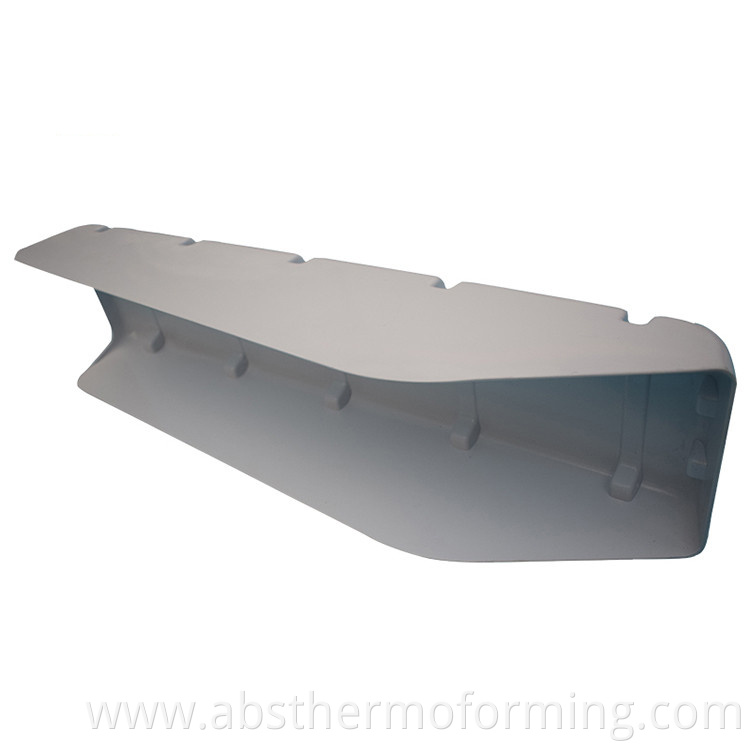

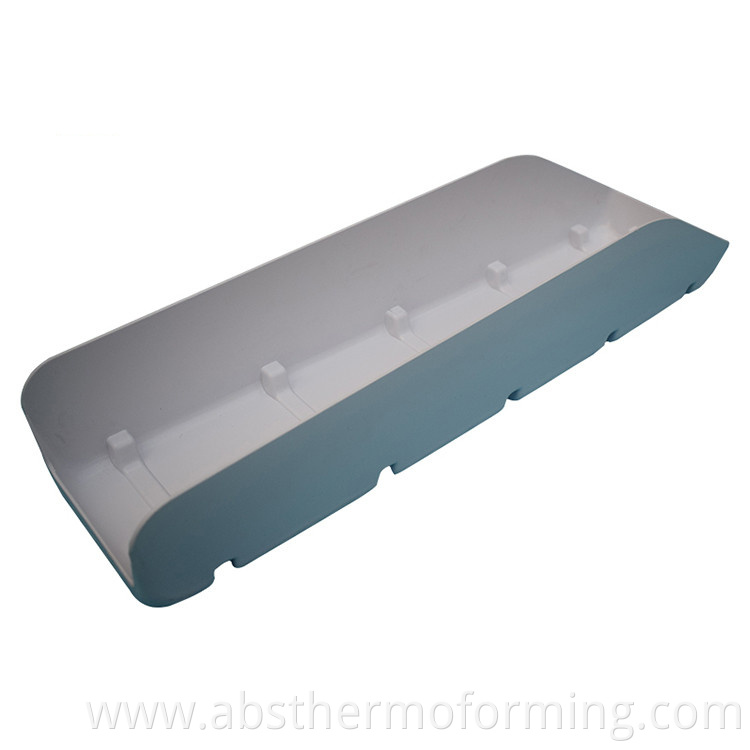

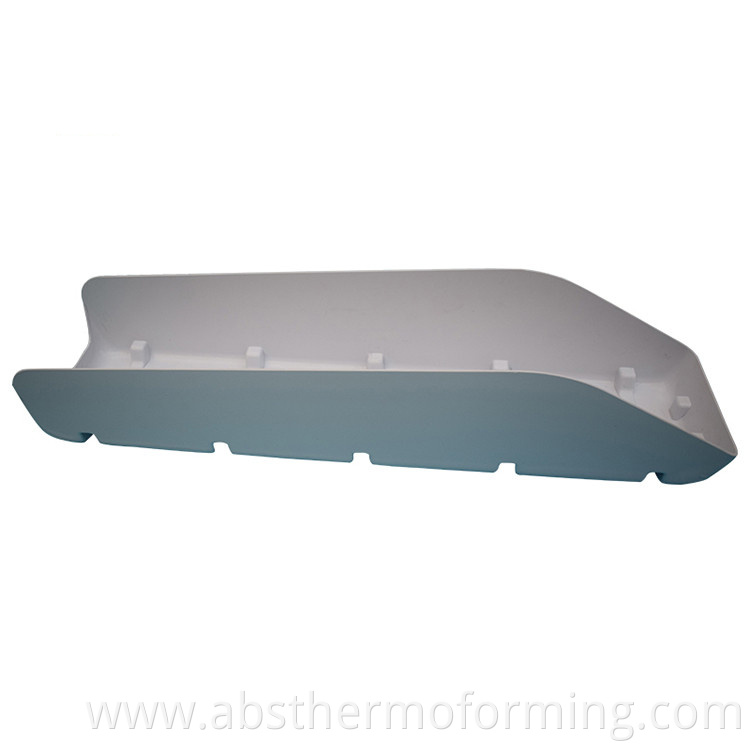

Custom shape thick Thermoforming Plastic ABS black cover

Thin Thermoforming and thick thermoforming are both processes used in the manufacturing of plastic products, but there are some key differences between the two.

1. Material Thickness: The most obvious difference is the thickness of the plastic material being used. Thin thermoforming typically involves plastic sheets that are less than 1/8 inch thick, while thick thermoforming involves plastic sheets that are 1/8 inch or thicker.

2. Heating Time: Because thin thermoforming involves thinner plastic sheets, it requires less heating time compared to thick thermoforming. Thin plastic sheets can be heated and molded more quickly, resulting in faster production times.

3. Cooling Time: Similarly, thin thermoforming requires less cooling time compared to thick thermoforming. Thicker plastic sheets retain heat for longer periods, so they take more time to cool and solidify in the desired shape.

4. Equipment and Tools: Thin thermoforming can often be done using simpler equipment and tools compared to thick thermoforming. Thin thermoforming can be done using Vacuum Forming machines, which are relatively simple and cost-effective. Thick thermoforming, on the other hand, may require more specialized equipment such as pressure forming machines or plug-assist forming machines.

5. Design Considerations: The thickness of the plastic material used in thermoforming affects the design considerations. Thin thermoformed parts are typically more flexible and can have tighter radii and more intricate details. Thick thermoformed parts, on the other hand, may have more structural integrity and can withstand heavier loads.

6. Cost: Thin thermoforming is generally less expensive than thick thermoforming. Thinner plastic sheets are cheaper to produce, and the equipment and tools required for thin thermoforming are often less expensive compared to those used in thick thermoforming.

Overall, thin thermoforming and thick thermoforming are used for different applications and have their own advantages and considerations. The choice between the two depends on the specific requirements of the product being manufactured.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.